If you’re looking into how to become a certified forklift driver, then this post is definitely for you. The role of a forklift driver, often referred to as a forklift operator, is a vital position across the industrial sector; in manufacturing, warehousing, logistics, and construction. As an industry professional, with specific skills, you’d be operating forklifts: specialised vehicles equipped with forks at the front, for lifting and moving heavy loads, pallets, and other materials.

Overall, your responsibilities are likely to include load handling (both loading and unloading), inventory management, safety compliance, material transport, equipment, team work, and few other things besides – including making sure you have the correct certification. And as a forklift operator, you’ll need to be skilled, safety-conscious, and detail-oriented to perform your duties effectively, taking great care to minimise the risk of accidents and injuries in the workplace.

That’s a short intro to the role of forklift driver, but beyond this point, we’ll cover various tips on becoming a forklift driver, including forklift training, the significance of forklifts in various working environments, the benefits of a career as a forklift driver, the different types of forklift certification, the importance of practical experience, safety practices, the essential skills required, and how to advance your career. So read on and learn all you could wish to know about being a forklift driver.

What does a forklift driver do?

Exploring the responsibilities and tasks of forklift operators

Forklift drivers have a range of responsibilities and tasks related to the safe and efficient operation of forklift equipment, across various industries. Most (if not all of them) would be listed in any forklift driver job description. Here are just some of them:

Operating forklifts: The first one on the list is fairly obvious – your central task would be to operate forklifts to move, lift, and transport materials and goods around, for example, a warehouse. This includes loading and unloading trucks, transporting items within a facility, and placing items in designated storage areas.

Material handling: Forklift drivers are responsible for lifting, stacking, and organising materials, goods, and products, often using pallets. They must ensure loads are balanced and secure before operating their forklift.

Safety compliance: As a forklift driver, you’ll need to stick rigidly to safety regulations – it’s of paramount importance. Operators must conduct pre-shift equipment inspections, report any malfunctions or damage, and follow established safety procedures to prevent accidents and injuries.

Inventory management: In warehouse and distribution settings, forklift drivers play a vital role in managing inventory by accurately storing and retrieving items, updating inventory records, and maintaining organised storage areas.

Communication: Although considered a ‘soft skill’, relevant to a number of different roles, effective communication with supervisors, colleagues, and other team members is essential for any forklift driver. The reason it’s important is because you’ll often receive instructions regarding specific tasks, and you must report any issues or incidents promptly.

Equipment maintenance: As a forklift driver, you’ll be expected to perform basic maintenance tasks, such as refueling, checking fluid levels, and conducting routine inspections, to ensure the forklifts are in proper working condition.

Certification and training: Forklift drivers have to comply with the certification and training requirements for forklift operation. This includes regular retraining and keeping up to date with safety standards.

Emergency response: Forklift drivers should be trained on how to respond to accidents or equipment malfunctions, and respond appropriately, ensuring the safety of themselves and those around them.

Housekeeping: This is a fairly basic but obvious task – forklift drivers are expected to keep work areas clean and organised to prevent hazards and maintain a safe and productive working environment. If we gave a list of every single, solitary duty of a forklift driver, this post would go on forever, so do your own research too, but the examples given above are some of the main tasks you’ll be expected to carry out.

The significance of forklifts in warehouse, construction, and manufacturing settings

Forklifts are an essential piece of equipment in warehouse, construction, and manufacturing settings right across the country. These versatile machines are the workhorses that help with the movement of heavy materials, goods, and products, playing a vital role in enhancing productivity across sites. In warehouses, forklifts enable the quick and precise stacking, retrieval, and organisation of goods or products, making the most efficient use of the space available and contributing to inventory control. In construction, they assist in the handling of bulky construction materials and equipment, ensuring projects are completed on time and improving worksite safety. In manufacturing, forklifts speed up the transportation of raw materials, components, and finished products within the facility, minimising production downtime.

Why Choose a Career as a Forklift Driver?

The benefits of becoming a forklift driver

If you’re seriously considering forklift training, then it’s well worth considering the benefits of becoming a forklift driver, as there are quite a few, making it an attractive career choice for many reasons. Here are a few of those benefits:

High demand: Forklift operators are in high demand right across the country, especially in industries like logistics, warehousing, manufacturing, and construction, as mentioned above. This demand ensures job opportunities and gives you job security.

Competitive wages: Forklift drivers often receive competitive wages, which can increase with experience and through gaining specialised certifications.

Stable job opportunities: Because so many industries utilise their skills, forklift operators can find work in a wide range of sectors, from retail and distribution to construction and manufacturing, offering flexibility in terms of available career choices.

Fast training: Training to become a forklift operator typically takes a short amount of time – around five days, initially – compared to many other careers, allowing you to get your licence and start working quickly.

Potential for growth: As you gain experience and expertise, you’ll have opportunities for career advancement, enabling you to move up to supervisory or managerial roles within your field, if you so wish.

Transferable skills: Forklift operation skills are transferable, meaning you can apply your expertise in various industries and locations.

Short-term and seasonal opportunities: Seasonal work is very much an option for forklift rivers, offering flexibility for those who want short-term or part-time employment during peak seasons, such as Christmas.

Health and safety knowledge: Forklift operators gain valuable knowledge about health and safety regulations throughout their careers, which can then be applied in various settings, making them an attractive proposition to employers.

License and certification: Getting a forklift license and certification is a recognised achievement that can enhance your employability and earning potential.

Who can become a forklift driver?

Age restrictions and required diplomas for entry into training programmes

If you’re looking at how to become a certified forklift driver, it’s worth noting that there are age restrictions and specific qualifications that are needed for entry into training programmes. To begin training, you must be at least 16 years old, in line with the legal minimum working age in the UK. However, many training providers may set a minimum age of 18 for their courses. In terms of educational qualifications, most training programmes don’t require a specific diploma or degree. Instead, they assess candidates based on their ability to meet the physical and health requirements for the role. If you’re looking to become a forklift driver you’ll need to demonstrate an understanding of health and safety practices and the ability to operate forklifts responsibly. Meet these standards and your training can get underway.

The skills required to become a forklift driver

Training programmes aside, becoming a forklift driver also requires a combination of essential skills and attributes to ensure safe and efficient operation of the machinery you’d be working with. Here are just some of the necessary skills and qualities you’d be expected to have:

Hand-eye coordination: Forklift operators need excellent hand-eye coordination to precisely manoeuvre the forklift and handle loads, especially in tight spaces or when stacking items.

Visual acuity: Good vision is vital for the role of forklift driver, for spotting obstacles, reading signage, and assessing the stability of the load you’re going to be carrying. A forklift operator should have good visual acuity, including depth perception and peripheral vision.

Attention to detail: Attention to detail is crucial when it comes to ensuring loads are balanced correctly and placed securely. Overlooking details can lead to accidents or damage to goods, and they could cost your company money.

Spatial awareness: Forklift drivers must have a strong sense of spatial awareness to navigate in confined areas, avoid collisions, and judge the distance and clearance around the forklift.

Problem-solving: The ability to assess and solve problems quickly, such as handling unexpected obstacles or determining how to stack items efficiently, is yet another important skill for forklift drivers.

Safety awareness: Safety is of paramount importance in forklift operation. Operators must be acutely aware of safety regulations, potential hazards, and best practices to prevent accidents and injuries.

Technical proficiency: This may seem obvious, and it’s something you’ll learn during your training, but a basic understanding of forklift mechanics and controls is a must. Operators must know how to start, operate, and maintain the forklift.

Adaptability: The ability to adapt to changing work environments and operational needs is crucial, as tasks and conditions can vary. One day you could be working on a construction site, the next you could be operating in a warehouse.

Time management: Efficient time management skills are essential to any forklift driver, to ensure tasks are completed within the allotted time – maintaining productivity and the smooth running of the site you happen to be working on These skills and qualities are essential to any forklift driver, so that they can safely and effectively perform their duties in various work settings, contributing to the overall efficiency and safety of operations for whichever organisation they’re working for.

How to become a certified forklift driver?

Types of forklift certification

Forklift certification is essential for anyone looking to operate forklifts in various settings. It may surprise you to know that there isn’t just one type of certification, there are, in fact, many different types, depending on the kind of forklift vehicle you’ll be operating and the environment in which it will be used. So, we’ve listed some of the most common types of forklift certification, including:

Counterbalance forklift certification: This is one of the most common types of forklifts used in warehouses and industrial settings. Certification covers the operation of counterbalance forklifts, which are used for lifting loads at the front of the vehicle. Before you take on this type of training, you may want to consider if the industrial sector is for you.

Reach truck certification: Reach trucks are designed for use in narrow aisle settings and are often used in warehouses. This certification covers the operation of reach trucks, including the stacking and retrieval of goods at height.

Telescopic handler certification: Telescopic handlers, or telehandlers, are used in construction and agricultural settings. This certification covers the operation of telescopic handlers, which can extend and retract to handle loads at various heights and distances.

Powered pallet truck certification: Powered pallet trucks are used for moving pallets within a warehouse or distribution centre. Certification for this equipment includes safe operation and load handling.

Pedestrian-operated pallet truck certification: This covers certification for pallet trucks that are manually operated by a pedestrian to move pallets on a flat surface.

Order picker certification: Order pickers are used in warehouses for picking orders from high racks. Certification for order pickers includes safe operation and order picking procedures.

VNA (Very Narrow Aisle) forklift certification: VNA forklifts are designed for use in very narrow aisles. This certification covers their safe operation in particularly tight spaces.

Moffett forklift certification: Moffett forklifts are mounted on trucks and are commonly used in the transportation and delivery industry. The certification covers their operation on and off the vehicle.

Multi-directional forklift certification: Multi-directional forklifts are designed for handling long and bulky loads. Certification includes safe operation and load handling techniques. Certification typically involves a combination of classroom training and practical skills assessment to ensure that you’re well informed about forklift operation and all related safety procedures. It’s important to obtain the right certification for the specific type of forklift you’ll be operating in your job, and have this available to show employers when necessary. Certification is usually valid for a specified period of time, after which retraining and recertification may be required.

How to actually obtain that certification

Obtaining forklift certification involves several steps to ensure that you’re properly trained and competent in forklift operation. The first thing to do is consider the specific type of forklift you’re looking to operate and select an accredited training course that covers that forklift. In doing this you’ll need to pick the training provider who offers the relevant course.

There are many to choose from, such as jungheinrich. Just make sure that the provider you choose is recognised by the relevant industry bodies, such as the Association of Industrial Truck Trainers (AITT) or the Construction Industry Training Board (CITB). Once you’ve chosen your provider, the next step is to actually register for the relevant training course. This will usually involve providing personal information, confirming eligibility, and paying any associated course fees. Once you’ve enroled, training will usually begin in a classroom setting, where you’ll learn all about forklift theory, safety regulations, and operation procedures.

Moving on, you’ll then come to the practical training element of the course, where you’ll learn, in practice, how to operate a forklift. This will give you hands-on experience in safely driving, stacking, and handling loads using the specific type of forklift you choose to be trained for. Once you’ve navigated the classroom-based and practical elements of the course, you’ll need to pass a skills assessment to demonstrate your competence in operating the forklift safely and efficiently. This will include completing manoeuvres like stacking, unstacking, and negotiating tight spaces.

Last but not least, you’ll need to complete a written test, to assess your understanding of forklift theory and safety regulations. Once you’ve successfully completed that written test, the practical assessment, and your classroom training, you’ll receive forklift certification, confirming that you’re now qualified to operate the type of forklift covered by your training, and can start looking at forklift jobs. Make sure you keep a record of this, as many employers will ask to see evidence of your training, including any certificates. Bear in mind that this certification doesn’t last forever – it’s valid for a specific time period, usually three to five years. So, you’ll need to complete recertification training every so often to continue working as a forklift operator.

Mastering Forklift Operation

The importance of practical experience to advance your career

Practical experience is essential for forklift drivers, as it equips them with the necessary skills and knowledge to operate forklifts safely and effectively, and builds their confidence in handling the equipment, helping to advance their careers. Learning basic manoeuvres, load handling techniques, and safety protocols through hands-on experience is invaluable.

Practical training enables forklift operators to develop the muscle memory and spatial awareness needed to navigate confined spaces, stack and unstack loads, and maintain balance while moving materials. In addition to this, understanding safety protocols and hazard recognition in real-world scenarios is crucial when it comes to preventing accidents and ensuring the wellbeing of both forklift operators and those working around them. To give you some examples, here are typical manoeuvres you may have to perform while operating a forklift:

- Forward and reverse driving: whichever direction you’re going in, this involves knowing how to start, stop, and change directions smoothly.

- Turning: Making controlled turns, allow you to move around obstacles and into tight spaces. Drivers must be skilled at turning without causing damage to the forklift, goods, or surroundings.

- Pallet pickup and placement: You’ll need to be able to safely approach a pallet, position the forks underneath it, and accurately place or retrieve it from a shelf or location. This involves precise alignment and controlling the height of the forks.

- Load stacking and unstacking: This is simply stacking goods, on pallets or racks, and unstacking them while maintaining load stability and balance.

- Side shifting: Adjusting the position of the forks horizontally to centre the load accurately or correct minor misalignments.

- Narrow aisle navigation: Navigating forklifts in narrow aisles is tricky, and demands precision and spatial awareness to avoid collisions and safely manage the load.

- Precision stopping: This involves knowing how to brake accurately, to prevent jolts or load instability, especially when carrying fragile or hazardous materials.

This doesn’t cover every manoeuvre. There are many others you’ll learn in both your theoretical and practical training. But it does give you an idea of what will be expected of you when operating a forklift.

Exploring Job Opportunities

The different roles available to forklift operators

As a forklift operator, you can pursue various job roles in different industries (hence the variety of courses available to cover the operation of different types of forklifts), depending on your skills, experience, and specific career goals. Some of those roles include:

Warehouse forklift operator: This is the most common role in the forklift world, focusing on the efficient movement of goods within a warehouse, including loading and unloading trucks, stacking and retrieving items, and managing inventory.

Construction site forklift operator: In construction settings, forklift operators handle materials such as building supplies, equipment, and tools, ensuring that they get to where they’re needed on the site.

Manufacturing forklift operator: In manufacturing facilities, operators move raw materials, components, and finished products, contributing to the production process overall.

Distribution centre forklift operator: These operators work in distribution centres, handling the flow of goods from arrival to distribution, including sorting, stacking, and loading them for transportation.

Freight and logistics forklift operator: In logistics and transportation, operators are responsible for loading and unloading cargo which comes in on trucks, ships, or aircraft, to facilitate the movement of goods.

Cold storage forklift operator: This is a specialised role, which involves working in refrigerated or frozen storage facilities, handling temperature-sensitive goods, such as foods or medicines.

You can, of course, move up the career ladder and diversify in terms of the roles you take on. For example, you could become a… Supervisor or manager – overseeing teams of operators and warehouse or logistics operations. Forklift instructor – training new operators so that they can obtain certification. Heavy equipment operator – expanding your skillset to operate other heavy equipment, such as cranes or excavators. In short, if you look to take on specialist training, or slightly alter your career path, there are a wealth of opportunities open to you as a forklift operator.

Becoming a forklift driver: in conclusion

Forklift drivers are very much in demand across the UK, in various sectors, including manufacturing, warehousing, logistics, and construction settings, so if it’s a career you’re looking to pursue, it certainly offers a degree of financial security – you shouldn’t be short of job offers. You’ll need to undertake the relevant training (and consider, in advance, what type of forklift you want to operate initially) to obtain the correct certification and, ultimately, a licence, but it’s well worth doing if you’re looking for work in the sectors previously mentioned.

You’ll also need to bear in mind that forklift operation involves a lot of additional responsibilities beyond just driving the machine, but there are a lot of benefits that come with being a trained forklift driver. And who knows, with dedication and hard work, you could open the door to a whole host of other career opportunities as you gain more experience. Whatever path you choose, good luck to you.

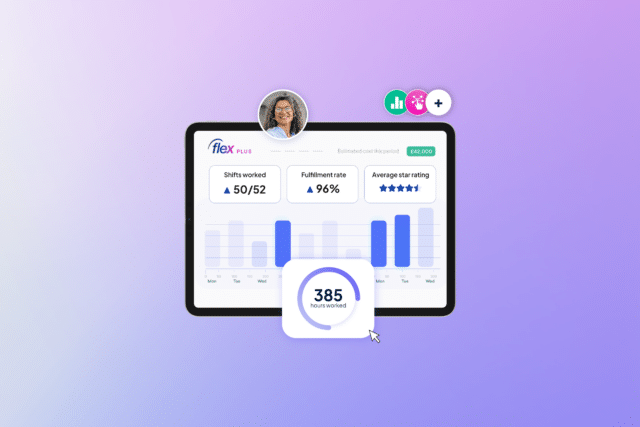

Download the Indeed Flex app today and benefit from a world of temporary work opportunities across all different industries and employers.